Polymat: Kitchen Grip Assistance is a silicone grip mat designed to tackle issues involved in the kitchen where the user cannot properly grip an item which will otherwise slide about.

For the first Unit 7 project we were asked to consider the concept of a multi-generational kitchen in the context of human-centred design. Minority groups including the disabled and elderly are often if not completely overlooked in design with a great many products promising to cater to their needs being ‘gadgety’ attempts to make a quick dollar.

Less than a quarter of people with physical disabilities are born with them, working with Alex (in the images above) we explored the idea of how even a minor impairment (in his case the depleted ability of the left side of his body) can greatly affect the manipulation of kitchen equipment. In particular because a lack of ability to stabilise an item leads to it sliding around.

I became interested in the idea of onset impairment or impairments that will go away eventually (eg broken limb). The market is full of gadgets and products ranging form the genuinely innovative to the obstructive and absurd.

I focused primarily on the kitchen sink, as washing dishes proves a key point of importance to food preparation, looking to create a responsive basin which provided variable resistance to pressure. The idea is that, where sliding objects becomes an issue, the user will simply push harder and the basin will grip the object.

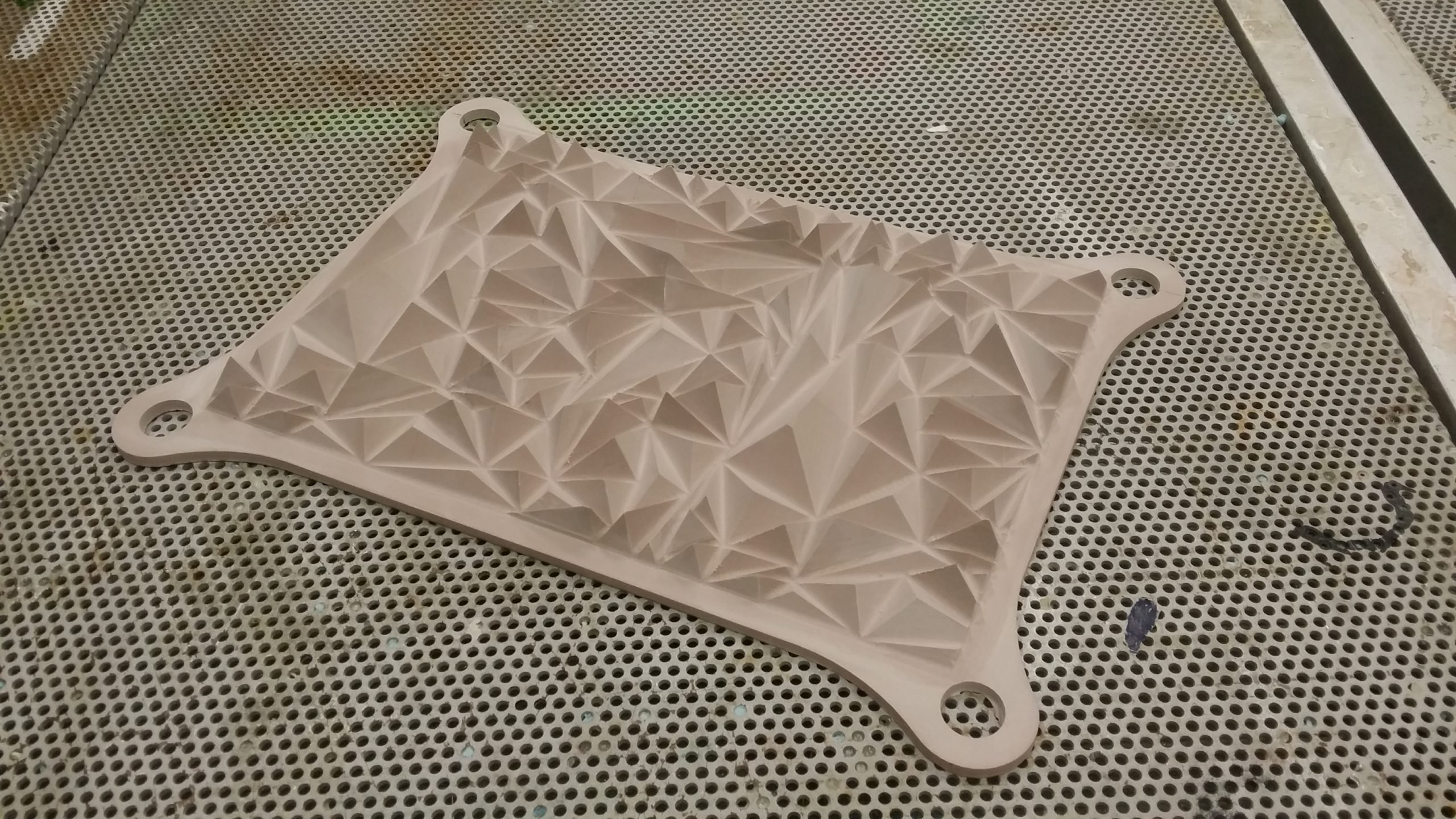

I needed a final appearance model to communicate the idea appropriately. The silicon samples served as proof of material properties but could not be cast at the right scale within time and budget constraints. I CNC routed the model in one piece with laser cut polymethacrylate adding detail underneath. A rubber spray was applied to create the correct surface effect.

This idea developed into a silicone mat with a variable texture surface designed to provide a range of friction across as large a range of items as possible. Many sample patterns were designed, 3d printed and cast to settle on the optimal pattern.

A final ‘looks-like’ model was produced largely by CNC milling, Laser cutting and painting with a silicone rubber. It was unfortunately deemed too costly to cast in the target material.

Reflecting on the project I wonder how imaginative the solution actually was. Visually striking perhaps but does it not simply add the plethora of Gadgets? Would users actually consider using it after or before impairment? Was there actually a change to the kitchen ‘System’? Did I play it safe?

This project especially was a chance to consider my position in relation to design, whilst I am more than happy with the outcome I find it imperative to recognise what this product is not, and what future outcomes must try harder to incorporate.